are you currently wanting to improve your drilling operations and minimize downtime? Among the most vital elements impacting performance could be the shaker screen. deciding on the suitable screen can noticeably influence mud movement, solids removing, and In general Expense-effectiveness. This information will present you with the essential information necessary to make an educated conclusion and select the perfect shaker display for the specific requirements, ensuring your drilling functions run smoothly and efficiently. As a number one shaker screen manufacturer, we comprehend the necessity of good quality and overall performance Within this vital place.

Table of contents:

Key variables to Consider When deciding on a Shaker display

differing kinds of Shaker Screens and Their programs

How the proper Shaker Screen Can enhance Drilling effectiveness

Key variables to Consider When picking out a Shaker monitor

choosing the appropriate shaker display screen needs mindful thought of several elements. initially, the type of drilling fluid being used performs an important position. Water-dependent muds have to have diverse mesh sizes and screen constructions when compared with oil-based muds. 2nd, the scale and type of solids getting removed are very important. Finer solids have to have finer mesh screens, but these can even be much more liable to blinding. Third, evaluate the move fee and pressure with the drilling fluid. High stream fees can place pressure on the monitor, probably bringing about untimely failure. at last, Assess the shaker's compatibility with distinct display screen forms. Not all shakers can accommodate all display screen layouts, so confirming compatibility is important. looking at these crucial aspects can help you narrow down your options and choose a shaker screen that optimizes your drilling functions. for instance, when you are employing a VSM300 shaker, discover possibilities such as the corrugated a person-piece steel sheet substitute screens read more from reputable suppliers.

Different Types of Shaker Screens as well as their apps

Shaker screens arrive in a number of types, Just about every suited to different programs. Woven wire mesh screens are a common selection, offering a value-efficient Answer for taking away an array of solids. Composite screens, built from various layers of mesh and aid elements, deliver Increased sturdiness and finer filtration capabilities. Pyramid screens, with their three-dimensional surface, provide elevated screening area and improved movement potential. Hook strip screens are created for easy installation and substitute, minimizing downtime all through display screen changes. Pre-tensioned screens are stretched and bonded to your body, delivering reliable stress and enhanced overall performance. Understanding the strengths and weaknesses of each and every variety will let you pick out the best choice to your drilling atmosphere.

How the appropriate Shaker Screen Can make improvements to Drilling performance

The correct shaker display assortment right translates to enhanced drilling efficiency. powerful solids elimination prevents the buildup of solids in the drilling fluid, sustaining its wanted properties and lowering put on on pumps along with other devices. This, subsequently, minimizes downtime for repairs and servicing. A well-decided on monitor also optimizes mud stream, avoiding pressure drops and making certain dependable drilling efficiency. Moreover, economical solids Manage minimizes the volume of waste created, reducing disposal expenses and minimizing environmental effect. By purchasing significant-quality shaker screens which are tailor-made to the certain drilling necessities, you'll be able to drastically increase effectiveness, decrease charges, and boost the general results within your drilling operations.

In summary, selecting the proper shaker display is very important for optimizing drilling operations. By considering elements like drilling fluid variety, solids size, movement rate, and shaker compatibility, you can pick out a display screen that maximizes solids removal efficiency and minimizes downtime. comprehension the different types of shaker screens as well as their applications helps you to make informed decisions which are tailor-made on your specific requirements. As you progress forward, take into account that investing in excellent shaker screens from the trustworthy shaker screen producer is definitely an expense from the very long-expression performance and achievements of your respective drilling functions. Don’t hesitate to consult with specialists to find out the ideal Resolution in your special issues and enhance your drilling procedure.

Neve Campbell Then & Now!

Neve Campbell Then & Now! Taran Noah Smith Then & Now!

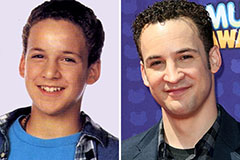

Taran Noah Smith Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!